Industrial Conveyors

Leading Manufacturers, Exporters, Wholesaler, Trader of Belt Conveyors, EN Mass Chain Conveyors, Overhead Chain Conveyor, Portable Belt Conveyors, Screw Conveyors and Slat Conveyors from Sangli.

| Business Type | Manufacturer, Exporter, Supplier |

| Belt Material | PVC/Nylon-Nylon |

| Speed Adjustable | Yes |

| Color | As per customer requirement |

| Size | 400mm – 2400mm |

| Length | As Per Customer Requirement |

Belt conveyor is designed for handling of Bulk materials. The Bulk material handling systems have innumerable areas of application like in Power Plant, Coal Handling, Bagasse Handling, Ash Handling , Sand Handling, Bag Handling, Bale Handling, Seed Handling, storage and loading into Ship storage and dispatch by rail/ road, mine materials etc

A Belt Conveyor consists of two or more pulley with continuous loop of material. One or both are powered, moving belt and the material on the belt forward. The powered pulley is called drive pulley and unpowered pulley called idlers.

Belt Conveyers are employed for conveying various bulk and unit loads along horizontal or slightly inclined paths and for transporting articles between various operations in production flow lines. They have found wide application in all branches of industry and are means of mechanical transport in foundry shops, in fuel supply systems of electric power stations, for ground and surface transport of coal and gangue in coal industry, for delivery of ores, coke and fluxes in metal making industries. They transfer building materials, fossil minerals, grain, sand, stone, etc. Belt Conveyors have become popular due to a high load-carrying capacity, large length of the conveying path, simple design, easy maintenance and high reliability of operation.

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Load Capacity | UPTO 100 TONS/HOUR |

| Feature | Excellent Quality, Heat Resistant, Long Life, Scratch Proof |

| Color | As Per Customer Requirement |

| Application | Moving Goods |

| Material | Metal |

| Country of Origin | India |

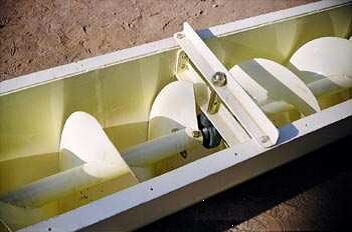

Food production in the country is rising steadily, so the demand for quality of the same. On the backdrop of liberalization and the increased competitiveness in the industrial sector, material handling with perfection becomes imperative. DK Industries gives you the cutting edge in this cut throat competition. DK Industries chain conveyors offer a better alternative. To be frank this is the best material handling system around DK Industries En- Mass conveyors can be used for handling a variety of free flowing material including sugar, grain, corn, beans, rice, flour, rape seed, Soya, corn meal, garden seeds, peas, sunflower seeds, peanuts, and even sawdust. It moves your material quickly, efficiently and with minimum damage. Material is fed past the upper return chain moves it then falls into the trough bottom, where the lower chain move it and forwards to the discharge side. When the additional material is introduced, it lies on the top of the moving material and is conveyed towards the discharge at the same rate as the chain. Drag chains carry the grains along entire depth of conveyor on special UHMWPE liners at an equal discharge rate and thus most of the material is gently carried on other layer of material. Plugging is eliminated as return chain limits the material to maximum level.

Unique features of DK Industries EN-Mass Chain Conveyor :

- Very low power consumption

- No breakdowns

- Special UHMWPE lining

- Complete safe operations

- Very gentle and highly efficient

- Modular / compact design

- No maintenance

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Application | Ovens Conveying Drying Cooling Painting Storage |

| Equipment Type | Overhead Chain Conveyor |

| Industries Catered | Automotive Painting Ovens Oil Industry Plastics Any |

| Materials Conveyed | Hanger Cradles Automotive Components Drums Frames Containers Bags and Sacks |

| Method | Mechanised Automated Speed control – VFD |

4 wheel Planar Chain with Alternate Load and Transmission Links for Guiding within Track for Horizontal, Inclined Bends and Overall Travel as per layout with Drive Unit, Tensioner and Control Panel.

Models

- Point Load Capacity 90 Kg Variable Speed Catter Piller Drive Model MD 150

- Point Load Capacity 60 Kg Variable Speed Catter Piller Drive Model MD 300

- Point Load Capacity 200 Kg Variable Speed Catter Piller Drive Model HD 200

Applications

- Various Processes involved in Washing, De-greasing, Drying, Phosphating, Powder Coating, Spray Painting, Dip Painting, Metalizing, Heating, Sand Blasting, Cooling, etc.

- Moving Inward/Outward materials or Semi-finished/Finished materials from one place or Department to the other

- Moving Work In Process (WIP) materials from one place to another

- Moving any materials using the Overhead Space, which is an effective tool for factories having space constraints

- Using overhead conveyors, we can handle multifarious things which include Leather materials, Green and Withered Tea Leaves, Glass, Ceramics, Electronic components / instruments, Sheet Metal components, Clothing Garments, Cartons, Furniture items, LPG Tanks, Stamped parts, Wood and metals, plastics, wood, Food items, Switch Gears, Ovens, Slurries, Sporting goods, Pharmaceuticals, etc.

- Foundry Casting Handling

- Heat Treatment / Tempering Furnaces

Industries where Overhead Conveyors can be effectively used

- House Hold Appliances Uses: For Painting of components, for carrying components to various sections in Assembly.

- Powder Coating and Metalizing Industries Uses: For carrying components from Paint Booth to Oven and Unloading

- Two Wheeler, Three Wheeler and Automotive Component Industries

- Forging, Casting and Metal Stamping Industries Uses: For carrying Castings for cycling and to carry finished casting for painting

- Lift and Elevators, Fire Extinguishers, Steel Wheel Industries – Uses: Painting of Sheet Metal components.

- Commercial Vehicles - Uses: To carry various components from one Section to other

- Refrigeration, Deep Freezers and Air-conditioning Industries – Uses : Painting of Refrigerator Cabinets and doors, pre-treatment of various steel components including cabinets and doors, carrying cooling unit from testing assembly line, carrying finished door to assembly line, Testing of Compressor Units, etc

- Shock Absorber Industries

- Pump Industries - Uses: To carry Castings, components for painting.

- Bicycle Industries – Uses: Painting of Fork, etc., Carrying components from Welding Shop to Paint Shop, Carrying components from Paint Shop to Assembly Line, Carrying fixing stickers, etc., carrying rims from Stores to Despatch, carrying Forks for brazing, carrying rims for buffing and plating, general handling operations inside the Plant, carrying rims from Rim Department to Stores.

- and other Industries where needed

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Belt Material | PVC/Nylon-Nylon |

| Speed Adjustable | Yes |

| Color | Black |

| Size | 10 Ft, 20 Ft, 30 Ft, 50 Ft |

DK Industries offers Portable Belt Conveyors of standard belt width 650mm, especially for bag handling to give capacity of 500 to 700 bags per hour for 50-100kg bags. Conveyors of suitable belt width as per customer’s individual requirements and site conditions are also available. Light weight but modular frame mounted on pneumatic A.D.V. tyres and castor wheel for easy movement. Side guards are provided at feeding point to guide bag on the belt. Being a portable unit it can be easily adjusted to any position and inter connected by link chutes. Idlers and pulleys are manufactured as per relevant IS and CEMA standards. Idlers are lubricated for life and properly sealed to avoid periodical maintenance. We use good quality being, standard drive units with suitable starter and switch unit. Procurement of standard interchangeable parts within a short period of notice and prompt after sales service are our special features. Less power consumption, good associated with the name "DK Industries"

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Spiral |

| Condition | New |

| Usage | To Conveythe material in Sugar factory, Rice mill, Oil mill etc |

| Specialities | Vibration Free |

| Product Type | Industrial Screw Conveyor |

We are Manufacturer, Supplier and Exporter of Screw Conveyors, Slat Conveyors. major application areas are Material Handling Systems and Material Handling Equipments etc. Our setup is situated in Miraj, Sangli, Maharashtra, India and majorly we serve our customers from countries like African Countries - Egypt, Algeria, Ghana, Ethiopia, Nigeria, Congo, Uganda, Kenya, Sudan, Tanzania, Zambia, Angola, Algeria, Zimbabwe, Namibia, Mozambique, South Africa, Mauritius etc.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Type | Slat Chain Conveyors |

| Material | Stainless Steel, As Per Customer Requirement |

| Certification | CE Certified |

| Length | As Per Customer Requirement |

| Application | Moving Goods |

| Color | Grey |

Slat conveyor is perfect for gently and quietly transporting product. This conveyor requires very little maintenance and will transport products over short or long distance.

Applications

- • Bag handling / Stitching Machines

- • Ovens, Food Industries

- • Foundries for Moulding box drying ovens

- • Paints Booth. Etc